Chemical Plant Design: A Neural Network Approach

Can a complex chemical plant be viewed analogously to a neural network?

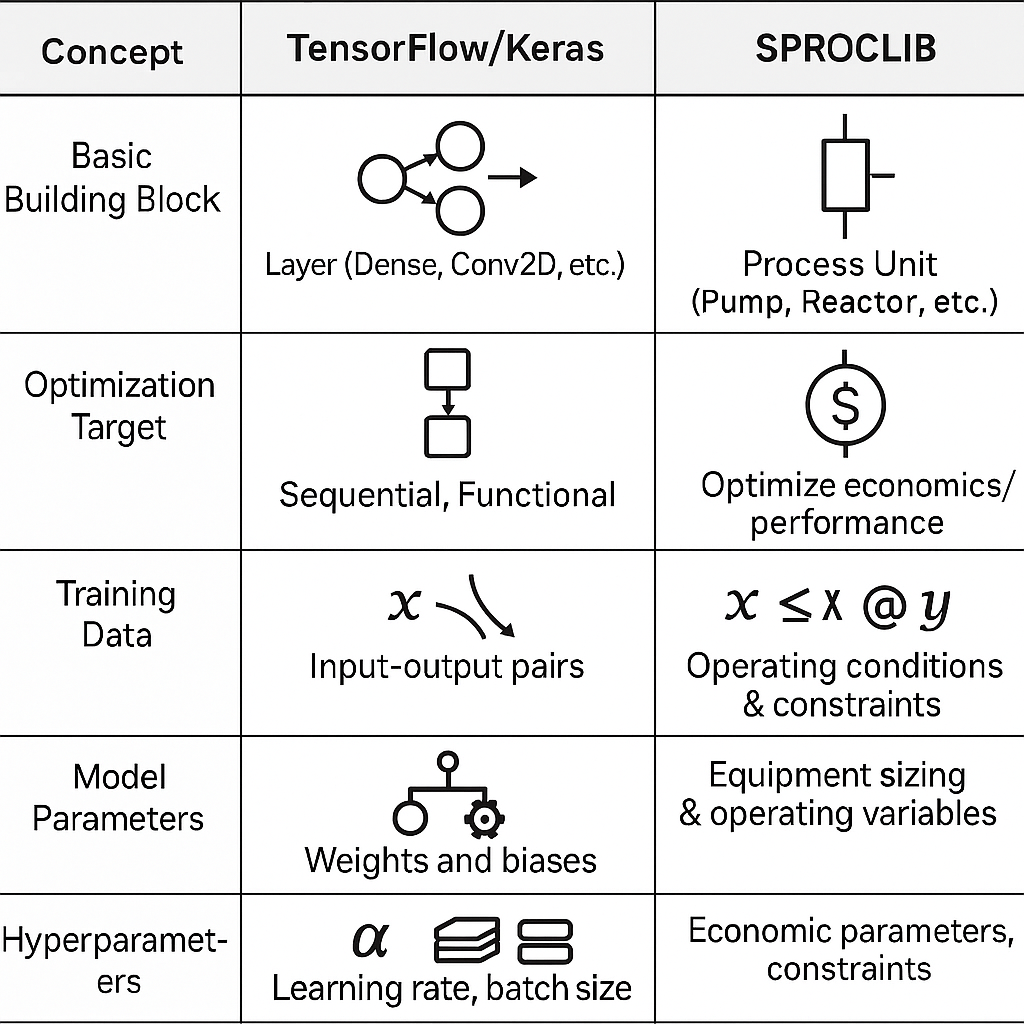

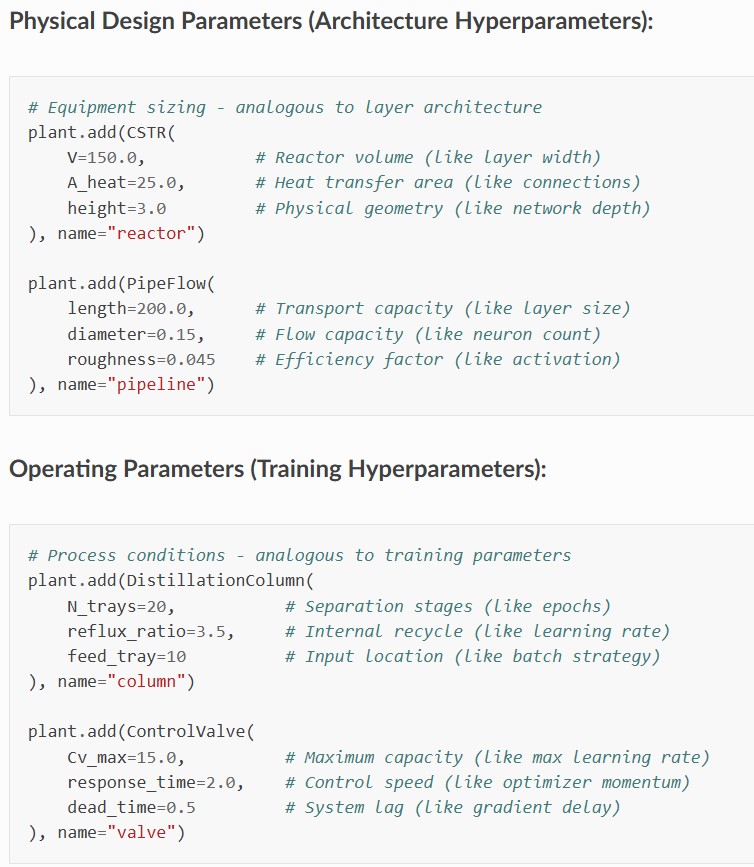

A central innovation in our approach for plant design is the conceptual mapping between hyperparameters in machine learning and design parameters in chemical engineering. Architectural design variables—such as reactor volume, pipe diameter, and number of distillation trays—correspond to network architecture in ML. Operational parameters—such as reflux ratio or valve response time—align with training hyperparameters like learning rate or batch size:

Inspired by Keras, we adopt the analogy: layers become unit operations, and pipes function as interconnecting neurons.

See here a more detailed comparison: SPROCLIB documentation

Our new Python library, SPROCLIB, supports grid search, random search, and automated tuning mechanisms analogous to Keras Tuner.

Integrating Neural Concepts into Chemical Plant Design

The design process follows an iterative and systematic workflow: initialize with a default configuration, conduct coarse parameter sweeps, refine via local optimization, and validate under varying conditions (e.g., feed composition or ambient temperature). This enhances robustness, ensuring resilient performance across operational uncertainties.

SPROCLIB: Chemistry Process Control Library

SPROCLIB is the beginning of a modern Python-based reimplementation of legacy tools like Modelica, Aspen, or gPROMS, with a focused scope on chemical process control. Hosted on GitHub, it is designed for modular versioning, collaborative development, and reproducible research.

Its core function is to serve as a curated, code-based repository of unit operations and controllers for chemical systems. Importantly! SPROCLIB models are not black-box LLM artifacts—they are readable, modifiable, and fully introspectable Python code, published under a permissive MIT license.

Each model implements a standardized .describe() method, allowing automated agents to access metadata, inspect system structure, and support digital twin development.

Semantic Plant Design API

SPROCLIB introduces a high-level abstraction: model-as-code—versioned, introspectable, and embedded into digital laboratory workflows. This shifts process control modeling from GUI-based environments to a code-first, modular, and extensible Python ecosystem, promoting automated reasoning, reproducibility, and rapid iteration.

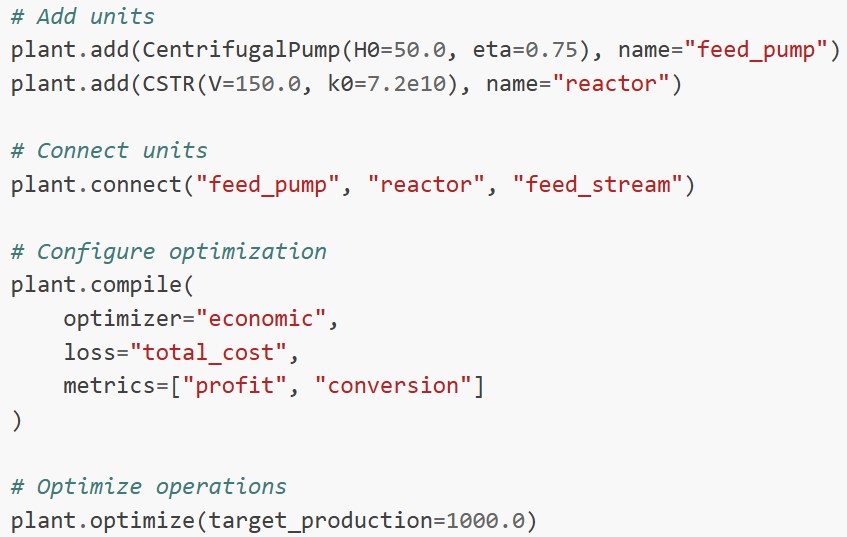

The Semantic Plant Design API offers an intuitive interface for modeling, optimizing, and simulating chemical plants. Users instantiate a ChemicalPlant object and sequentially add units (e.g., pumps, reactors, columns, valves) via plant.add(…). Units are connected through plant.connect(…).

Once configured, the plant is compiled with defined objectives (economic, environmental, safety) and performance metrics (e.g., cost, yield, conversion). Optimization—akin to training—is executed with plant.optimize(…), supporting constraints and multi-objective weighting.

The system supports dynamic simulation (plant.simulate(…)), performance evaluation (plant.evaluate(…)), summary reporting (plant.summary()), and multi-format export (JSON, XML, PDF, Python).

SPROCLIB marks a paradigm shift: it simplifies setup, unifies plant lifecycle modeling, and democratizes access through open-source distribution. Integrated with Python’s scientific stack, it supports real-time optimization, scenario analysis, and AI-based control.

For Paramus.ai’s TECH agent, developed for intelligent chemical process reasoning, SPROCLIB forms the technical core, enabling meaningful operation within complex process environments. It is part of the paramus foundation libraries.

Github: https://github.com/Gressling/sproclib; Quick example: https://github.com/Gressling/sproclib/tree/main/examples

Documentation: https://sproclib.readthedocs.io/en/latest/

BLOG: https://paramus.ai/blog/chemical-plant-design-a-neural-network-approach/